General News

High-strength strapping tape for vertical balers - escort your recycled materials safely

Introduction

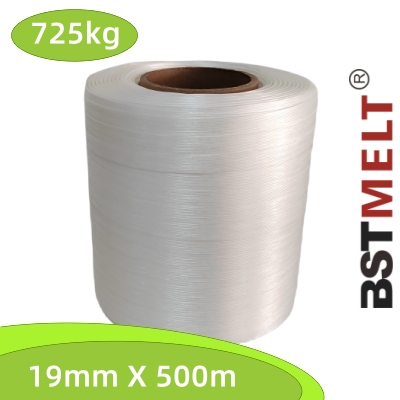

In the fields of waste recycling, logistics and industrial production, strapping tape is the core tool to ensure that materials are firmly strapped and reduce transportation losses. As the "golden partner" of vertical balers, our professional-grade strapping tape takes high strength, wear resistance and strong adaptability as the core concept to help you achieve efficient strapping and cost-controlled one-stop solutions.

Why choose our strapping tape for vertical balers?

1. **High-strength tensile resistance to ensure transportation safety**

- Made of high-quality polyester (PET) or polypropylene (PP) material, with a tensile strength of more than 780kg, it can withstand the extreme pressure of the vertical baler.

- Accurate tension control to avoid the risk of loose or broken strapping, ensuring that recycled materials such as waste paper, plastics, and metals are stable and not loose during long-distance transportation.

2. **Corrosion-resistant and moisture-proof, adaptable to complex environments**

- Special surface coating process, moisture-proof and rust-proof, resistant to acid, alkali, and oil corrosion, suitable for wet warehouses, open-air stacking and other scenarios.

- Stable performance under extreme temperatures (-30℃ to 80℃), no brittleness or deformation problems.

3. **Strong compatibility, reducing use costs**

- Adapt to mainstream foreign vertical baler models, no need for additional equipment modification.

- Provide a variety of widths and thicknesses to flexibly match different packaging needs.

4. **Environmentally friendly and sustainable, helping green production**

- 100% recyclable materials, in line with EU RoHS and REACH environmental standards, reducing corporate carbon footprint.

- Low-energy production process, single roll length can reach 1,100 meters, reducing replacement frequency and saving operating costs.

Application scenarios: Providing efficient solutions for multiple industries

- **Waste paper recycling station**: Quickly bundle waste cartons and newspapers to improve loading efficiency.

- **Plastics processing plant**: Stabilize loose materials such as PET bottles and films to prevent them from scattering during transportation.

- **Metal waste center**: High-strength bundling of heavy waste materials such as aluminum cans and copper wires to reduce the loss rate.

- **Logistics warehousing**: Strengthen pallet cargo to ensure long-distance transportation safety.

Customer testimony

- **A European waste paper recycling company**: After use, the bundling loss rate is reduced by 40%, and the annual cost savings exceed 20,000 euros.

- **Southeast Asian plastic processing plant**: "Stable quality helps us cope with the challenges of high humidity in the rainy season, and there have been zero complaints in three years of cooperation!"

Our service commitment

✅ **Quality assurance**: Passed ISO9001 certification and provides authoritative test reports.

✅ **Customized service**: Supports LOGO printing, size customization and bulk purchase discounts.

✅ **Fast delivery**: Global air/sea logistics network, direct to overseas warehouses.