General News

Baler Strap: An Essential Packing Material for Modern Enterprises

In today's industrial environment, businesses are processing large volumes of cardboard, plastic, and other waste materials every day. To achieve effective recycling and disposal, many companies utilize balers to compress and bundle these materials. Among these, Baler Strap plays a crucial role as a key consumable, ensuring the speed and safety of the bundling and transportation processes.

What is Baler Strap?

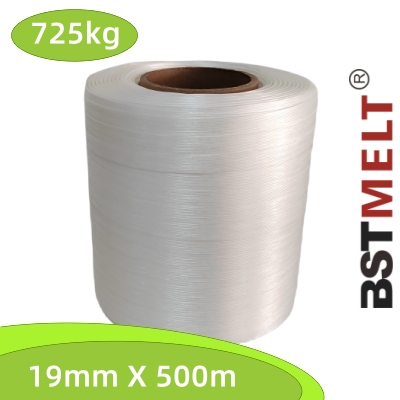

Baler Strap is a specialized binding material designed for use with balers, capable of effectively bundling various waste types, such as cardboard, plastic, and metal. It is typically made from high-strength polypropylene or polyester, offering durability and resistance to wear and corrosion, making it suitable for long-term storage and transportation. In addition, the lightweight and high tensile strength of Baler Strap make it one of the ideal choices for businesses during the bundling process.

Why Do Enterprises Need Baler Strap?

1. Improved Recycling Efficiency

In modern enterprises, recycling is a key measure for enhancing sustainability and reducing operational costs. By using Baler Strap, businesses can effectively compress loose waste materials into compact bales, improving the use of space at the site. This process not only speeds up the handling of waste but also reduces the required transportation space, thereby lowering shipping costs.

2. Ensuring Safety

For many companies, the stability of bundled materials directly impacts equipment and employee safety. Baler Strap securely holds packaged items together, reducing the risk of slipping and scattering during handling and transit, which ensures operational safety. In addition, high-quality straps can withstand significant pressure and weight, further enhancing transportation safety.

3. Saving Labor Costs

Utilizing Baler Strap alongside automated balers can significantly reduce manual labor requirements. The combination of balers and efficient binding materials can quickly complete the bundling process, diminishing the need for dedicated manpower. This not only improves work efficiency but also allows employees to focus more on other essential tasks.

Types and Selection of Baler Strap

The market offers various types of Baler Strap to suit different business needs, including variations in width, thickness, and material. Companies should consider several factors when selecting the most appropriate binding material:

Material Strength: Choose a strap with adequate strength based on the weight of the items being bundled to ensure it won’t break under heavy loads.

Weather Resistance: For items that need to be transported outdoors, selecting materials resistant to UV rays and temperature changes is crucial.

Compatibility: Ensure the selected Baler Strap is compatible with the existing baling machines to facilitate an efficient bundling process.

Best Practices for Using Baler Strap

To maximize the effectiveness of Baler Strap, businesses should follow some best practices:

Regular Checks: Regularly inspect both the baling machines and the Baler Straps to ensure there are no damages or deterioration. Timely replacements are critical for safety.

Proper Tensioning: During the bundling process, ensure that the Baler Strap is properly tensioned to avoid item movement during transportation.

Operator Training: Conduct training for employees on the correct operation of balers and Baler Straps to optimize workflows and reduce accidents.

Conclusion

Baler Strap serves as an important packing consumable, significantly impacting waste handling and sustainability for businesses. Selecting the right Baler Strap and using it properly can greatly enhance operational efficiency while ensuring safety and contributing to environmental efforts. In the modern industrial landscape, using high-quality Baler Straps has become a vital step for businesses to achieve efficient and sustainable operations.

See More News